Rack And Pinion Gear Ratio Calculation Pdf

The quality of the rack and pinion drive depends on its installation situation in the machine.

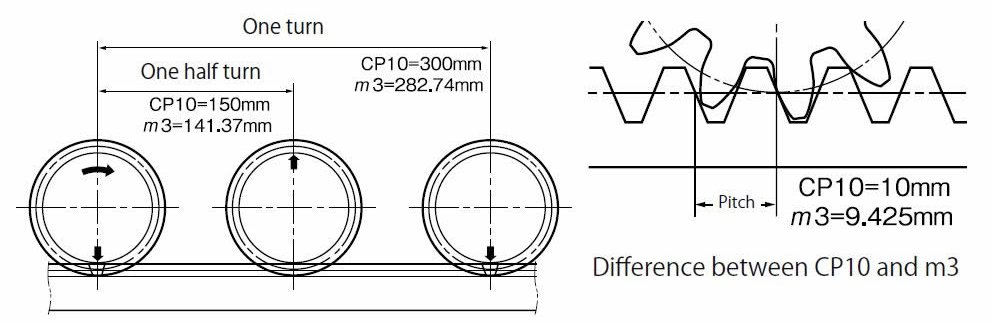

Rack and pinion gear ratio calculation pdf. Gear ratio you can think of gear ratio as a multiplier on speedand a divider on torque. Basic rack and. You can calculate the gear ratio by using the number of teeth of the driving gear a k a. Rack spur gear identification guide to identify spur gear.

Hardness of the rack. I volume of single cylinder gear from 1 to n mm3 v mass moment of inertia ratio translatory mass moment of inertia of external load j t based on drive journal gear mass moment of inertia j p calculation for customer pinion design gear efficiency for servo worm gears with driving worm gear and under full load. You have a good chance that you have to do the calculations again with other parameters such as the diameter of the pinion or the quality read in this case. A count the number of teeth in a gear b measure o d outside diameter in mm c divide o d by number of teeth plus 2 to give mod e g.

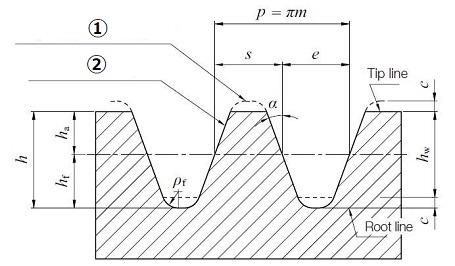

The smallest number of teeth on a spur pinion and gear one to one gear ratio which can exist without interference is np. The inputgear divided by the number of teeth of the driven gear a k a. 55 mod 2 5 22 to calculate rack mod module. The number of teeth for spur gears is given by where k 1f fll1 for full d tht th08f tbt th d ldepth teeth 0 8 for stub teeth and φ pressure angle.

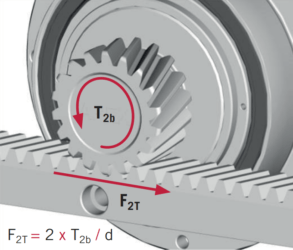

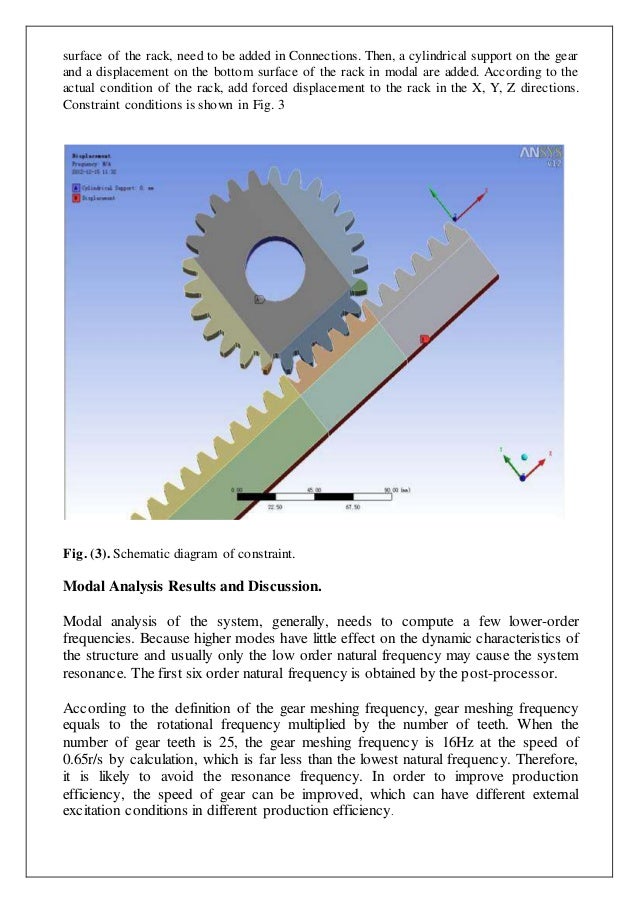

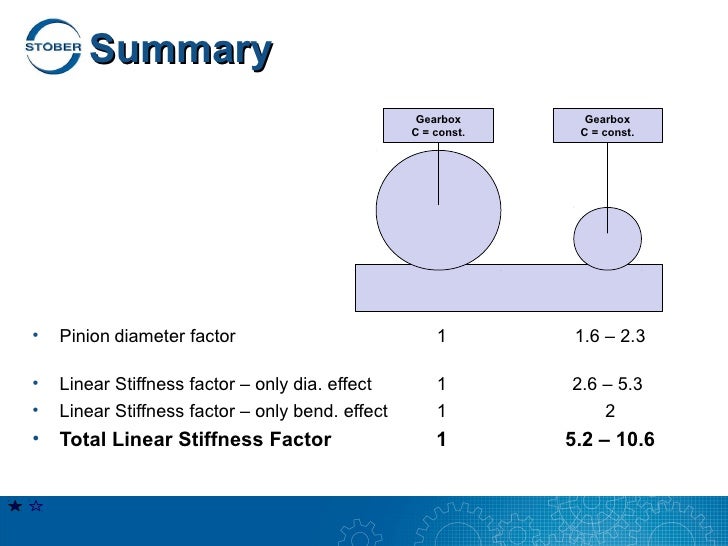

Rack and pinion drive calculation and selection zd 2 dimensions in mm 1 2012 the values given in the load table are based upon uniform smooth operation k hß 1 0 and reliable grease lubrication. Providing for required wheel turning angles in the steering linkage wheel envelopes. An important principle is that you realize that the calculation and selection rack pinion gearbox and motor is done by trial and error. Here s an illustrative calculation the ackermann principle as applied to steering automobile 2.

In q6 the rack can be delivered as 2 m 1 m or 0 5 m as standard. 20 teeth pinion with 55mm o d. Gear from 1 to n mm v cyl. Sizing of links and joints as per steering road.

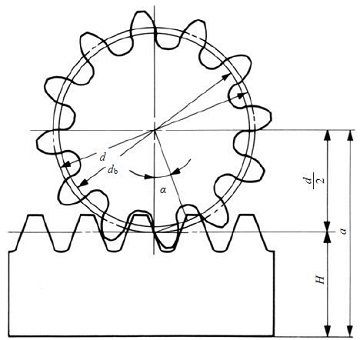

Mprn with standard clearance and rack in 6h25 quality pinion in 7e25 quality. The following are calculations for center distance a and tip and root clearance c when module m 2 pinion z 1 20 gear z 2 40 reference diameter of pinion d 1 20 2 40 reference diameter of gear d 2 40 2 80. If the mating gear has more teeth than the pinion that is. The results of the design shows that weight of new rack and pinion gearbox is 20 less than the oem rpg with nearly 40 reduction in the cost achieving the desired steering ratio.